Introduction

The semiconductor industry is at the core of modern technology, powering everything from smartphones to supercomputers. As demand for smaller, faster, and more efficient chips increases, manufacturers face immense pressure to innovate. Artificial intelligence (AI) has emerged as a transformative force in semiconductor fabrication, making production processes smarter, faster, and more sustainable.

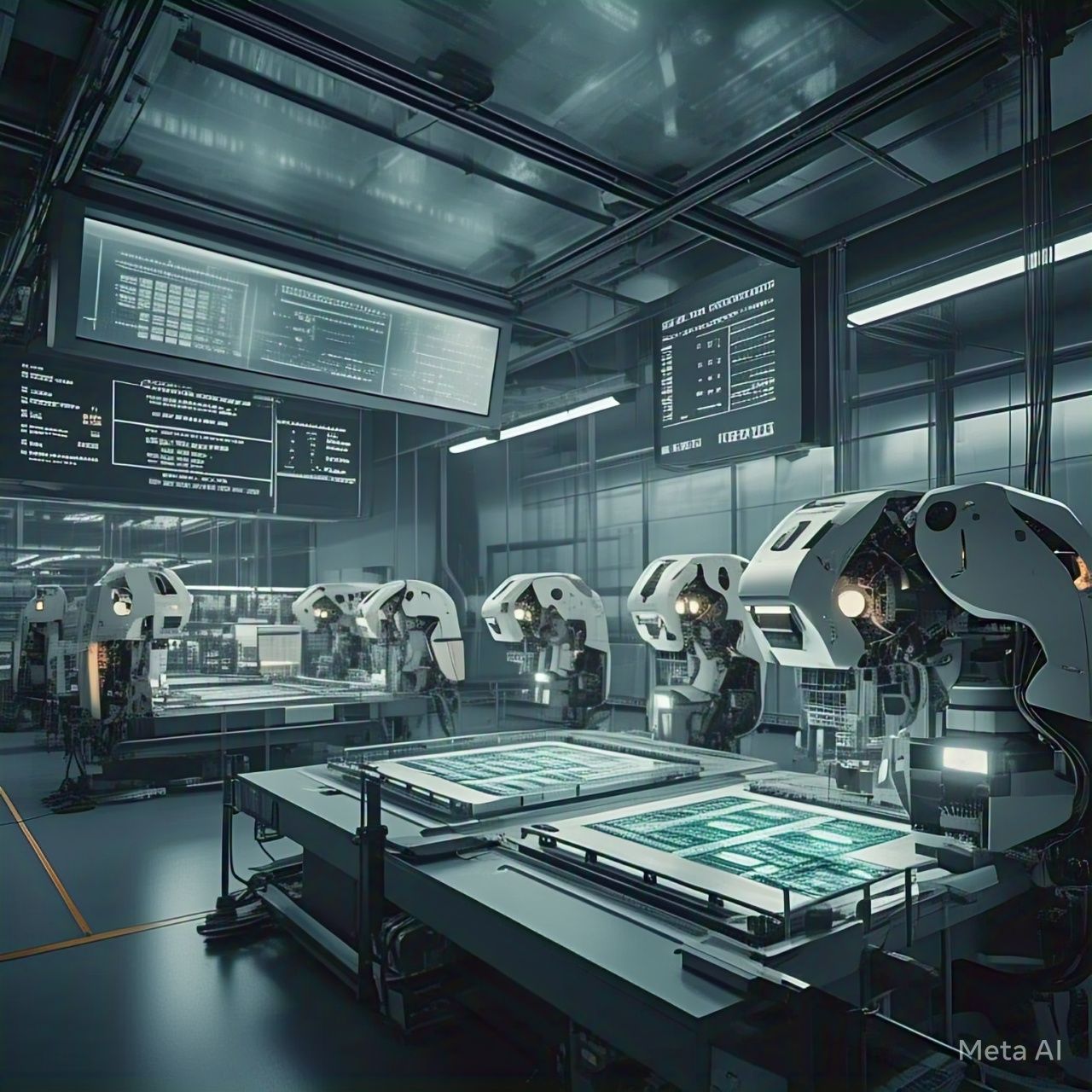

How AI is Revolutionizing Semiconductor Fabrication

AI-driven technologies are optimizing every stage of semiconductor manufacturing, from design to production and quality control. By leveraging machine learning, predictive analytics, and automation, AI is enhancing efficiency, reducing waste, and improving overall yield.

1. Smarter Design and Simulation

Traditional semiconductor design relies on iterative processes that can take years to refine. AI-powered design tools use deep learning algorithms to simulate and optimize chip layouts, significantly reducing development time. AI-driven electronic design automation (EDA) tools can analyze vast datasets, identify patterns, and generate designs that maximize performance while minimizing power consumption.

2. Faster Manufacturing Through Automation

AI-powered robots and machine learning models are revolutionizing wafer fabrication. These systems can detect inefficiencies in real time, enabling faster adjustments to processes such as photolithography, etching, and deposition. AI-driven predictive maintenance minimizes downtime by forecasting potential equipment failures before they occur.

3. Greener and More Sustainable Production

Sustainability is a growing concern in semiconductor fabrication due to high energy consumption and material waste. AI optimizes resource allocation by monitoring energy usage and reducing material waste. Machine learning models predict optimal chemical usage, minimize defective wafers, and improve recycling processes, contributing to a greener semiconductor industry.

Real-World Applications of AI in Semiconductor Manufacturing

Many industry leaders have already integrated AI into their fabrication processes:

- TSMC uses AI-driven analytics to enhance wafer defect detection, improving yield rates.

- Intel leverages machine learning for predictive maintenance, reducing machine downtime.

- Samsung employs AI-powered automation in cleanroom environments, ensuring precision in manufacturing.

The Future of AI in Semiconductor Fabrication

As AI continues to evolve, its role in semiconductor manufacturing will only expand. Future advancements in quantum computing, edge AI, and generative AI models will push the boundaries of chip design and production efficiency. Companies investing in AI-driven fabrication will gain a competitive edge, producing faster, more efficient, and environmentally sustainable chips.

Conclusion

AI is reshaping semiconductor fabrication by making processes smarter, faster, and greener. From intelligent design tools to automated manufacturing and sustainability initiatives, AI is driving the future of the semiconductor industry. As technology advances, the integration of AI will become essential for companies looking to stay ahead in this rapidly evolving landscape.